Please feel free to consult with us on anything related to glass processing. We are capable of working with a

variety of materials, including single crystal materials.

We stock a wide range of products from Corning, SCHOTT, and Eagle to meet the diverse needs of our

customers.

We have extensive experience with custom orders for lenses, mirrors, and prisms.

Even in cases where other companies may quote a high price, please do not hesitate to contact us.

Lens

Lens Mirror

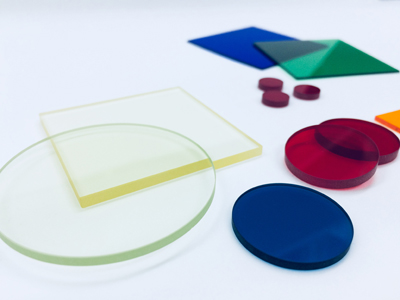

Mirror Color Glass

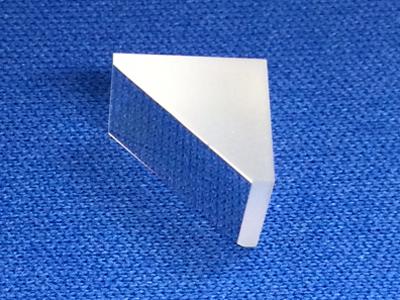

Color Glass Prism

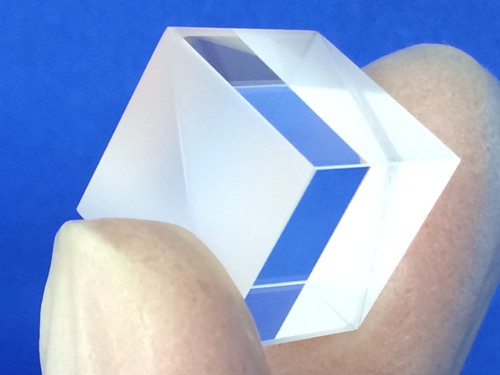

Prism Beam splitter

Beam splitter ND Filter

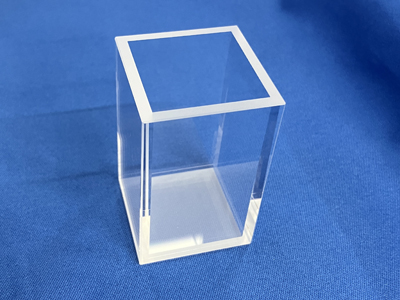

ND Filter Glass Cell / Fused Silica

Cell

Glass Cell / Fused Silica

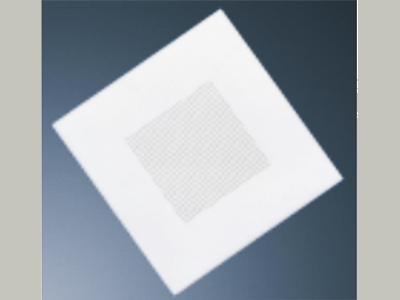

CellCold Ablation processing is a technology that enables precise microfabrication without leaving thermal

effects on the material.

This technique utilizes pulsed laser irradiation with ultra-short pulses, such as femtosecond lasers or

picosecond lasers.

In general, irradiation with ultra-short pulses shorter than 10 picoseconds generates minimal thermal

effects on the target material.

This makes it possible to microfabricate hard-to-process materials and high-hardness brittle

materials.

Its high peak energy induces nonlinear effects, which are used for cutting transparent materials and

micro-drilling.

Additionally, unique effects that do not appear in other laser thermal processes, such as generating

periodic structures on almost any material surface, have been observed, and the range of applications

continues to expand.

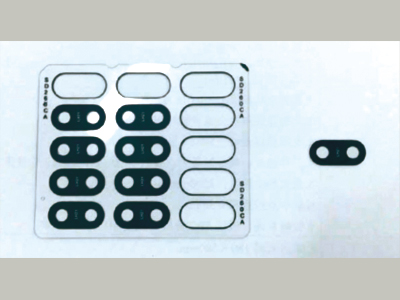

Glass

Cutting and Marking

Glass

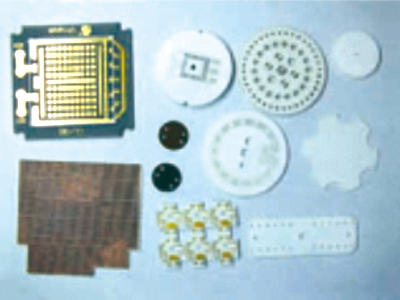

Cutting and Marking Ceramic Processing

Ceramic Processing

Drilling High-Hardness Brittle Materials

Drilling High-Hardness Brittle Materials